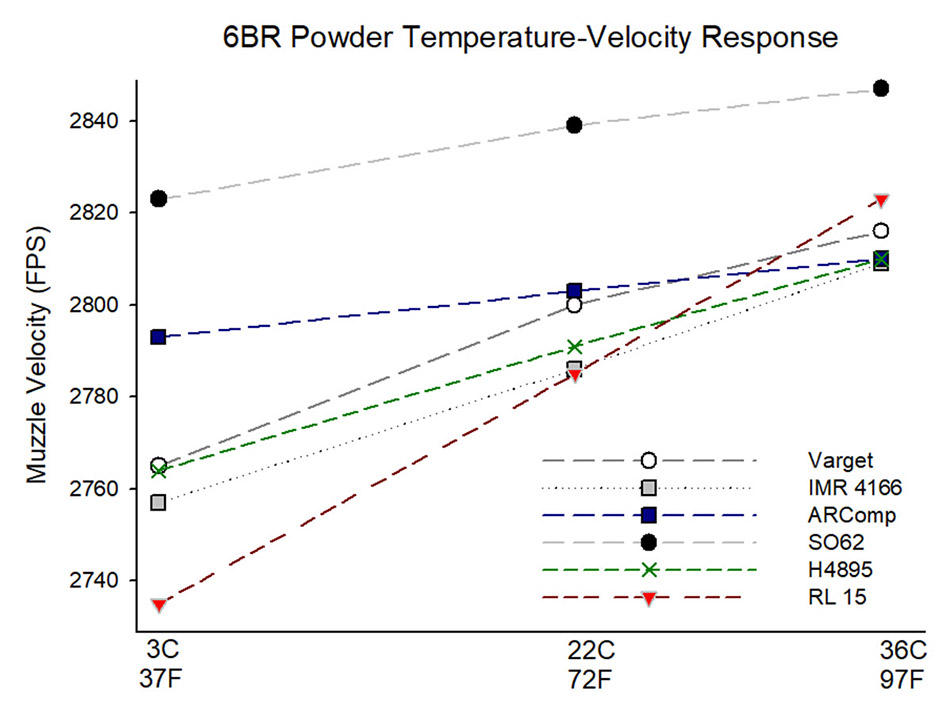

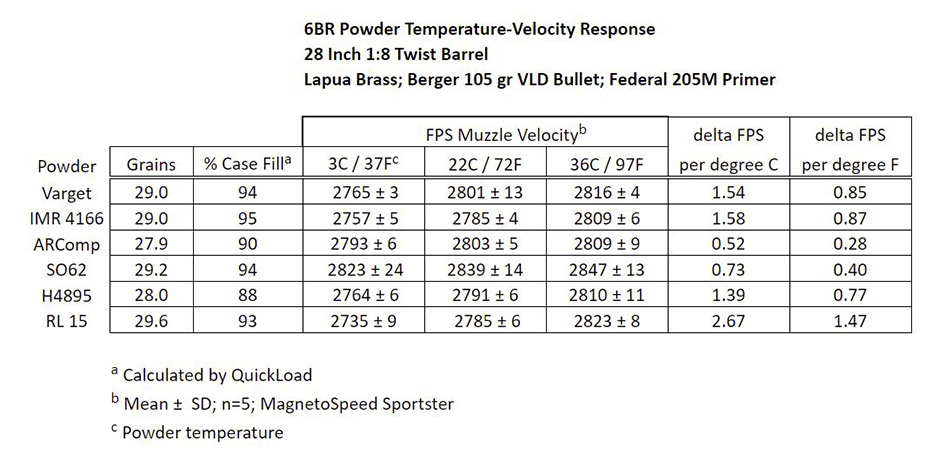

6BR Powder Temperature-Velocity Responses

The goal of this test was to identify substitute or replacement powders for Varget in my 6BR match rifle. A desirable powder would produce only small variations in muzzle velocity across temperatures that are commonly encountered during matches in North and Central Florida (40F to 95F) and would show only small variations in shot to shot velocity at the same temperature.

Methods:

A. Powders tested

1. Varget: (Lot # 80306207171) Manufactured by: Thales Australia Ltd (ADI), Mulwala, NSW, Australia. Brand rebadge and distributed by: Hodgdon Powder Company, Shawnee, KS, USA.

2. IMR 4166: (Lot # 80618156415) Manufactured by: General Dynamics Ordnance and Tactical Systems, Valleyfield, Québec, Canada (Similar to XPR40C2). Brand Rebadge and distributed by: IMR Powder Company, Shawnee, KS, USA

3. AR-Comp: (Lot # 15036 Z 051821) Manufactured by: Eurenco Bofors AB, Karlskoga, Sweden (Similar/Identical to RP-34TZ) Brand rebadge and distributed by: Alliant Powder, Anoka, MN, USA

4. Lovex S062 - Shooters World Precision Rifle Powder: (Lot# poorly legible stamp on label " ___21_ 320")

Manufactured by Expolsia, a.s., Pardubice, Czech Republic (Lovex S062). Brand rebage as Shooters World Precision Rifle Powder and distribution by Shooters World, LLC, Tampa, FL,

5. H4895: (Lot# 8111320 7227)

Manufactured by: Thales Australia Ltd (ADI), Mulwala, NSW, Australia (Similar to AR2206H). Brand rebadge and distributed by: Hodgdon Powder Company, Shawnee, KS, USA

6. Reloader 15 (RL 15):

(Lot # 15051Z010622) RL 15 is made is Sweden (presumably by Eurenco Bofors AB, Karlskoga, Sweden) Brand rebadge and distributed by: Alliant Powder, Anoka, MN, USA

B. Test Cartridge

+ Lapua 6BR Brass: Reloaded for 6th time with no neck trimming. The neck was annealed at each reloading. Necks were resized with a Redding Competition Bushing Neck Sizer die (0.266 bushing) except for 5th reload brass which was resized to bump shoulders back to first form fire conformation with a Whidden Gunwerks Click Adjustable FL Bushing Sizer die with 0.265 bushing.

+ Berger 105 gr VLD bullet seated to COAL 2.38" (0.015" jump to lands)

+ Federal GM205M primer

C. Rifle Used:

Eliseo R5 rifle with 5-round magazine and with Stiller TAC 30 action and 28 inch Bartlein barrel with 1:8 twist 5R rifling. The chamber had been cut for no-trim necks. The barrel had 2910 rounds through it at the start of the test.

D. Cartridge Powder Measurement

Powders were dispensed/measured with an AutoTrickler V2 system (Adam MacDonald, New Brunswick, Canada) on an Entris Sartorius Balance. The AutoTrickler with further manual charge adjustment delivered powders within a 1-2 granule range of the target weight.

E. Cartridge Powder Temperature Control

Three or two cartridges each were enclosed in water-tight 50ml centrifuge tubes and brought to target temperature by placing tubes in Yeti Rambler 36oz vacuum insulated bottles containing water at desired temperature for at least 2 to 2.5 hours.

3°C: Centrifuge tubes (2 to 3) containing cartridges at room temperature (about 21°C) were transferred to the Yeti bottles that were filled with water at 2°C. They were held for 2.25 hours to equilibrate. Water temperature was measured again with a mercury scientific thermometer (Fisher Scientific) immediately before removing the tubes to load and fire the cartridges (3°C) as a measurement of powder temperature.

22°C: Centrifuge tubes containing cartridges at room temperature (about 21°C) were transferred to Yeti bottles and filled with water at 22°C. They were held for 2 hours to equilibrate.

36°C: A similar procedure to the 3°C procedure was used except the Yeti bottles were filled with water at 38°C. They were held for 2.5 hours to equilibrate.

F. Firing and Chronometer Procedure

Tests were run on March 29, 2022 in Gainesville (elevation 176 feet above sea level).

Ambient conditions during tests were: 3C - 64F; 74% humidity; 30.08 mm Hg; 22C - 80F; 53% humidity; 30.00 mm Hg; 36C - 80F; 65% humidity; 30.03 mm Hg; At each temperature, two rounds were fired through the rifle to prepare the barrel and test chronograph function. One tube at a time was removed from the Yeti bottle, opened, and cartridges were dumped on a towel. Five rounds quickly were loaded by a Nitrile-gloved hand into the magazine and loaded in the rifle. Five shots immediately were fired within 12 to 15 seconds verifying each shot was measured by the MagnetoSpeed chronograph. The mean and SD of the 5 shots was recorded and each shot speed was recorded. Memory was erased after recording, and the next five cartridges were removed from tubes and loaded into the magazine and fired. The barrel was cooled for 8 minutes (5 minutes with a chamber chiller) after 17 shots.

Results/Data:

|

Table 1 |