Comparison of 223 Remington Brass for AR-15 Service Rifle

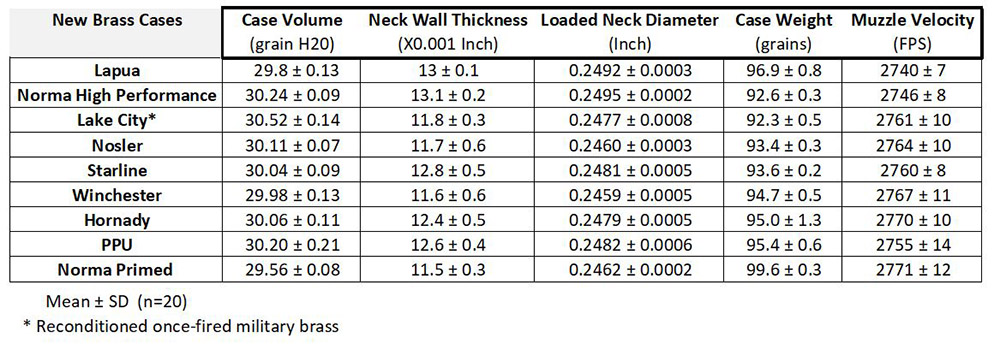

This study summarizes physical properties and bullet velocity performance of 9 brands of 223 Remington brass cases for use with AR-15 service rifles with 20-inch barrels used for NRA High Power Across the Course (XTC) matches. The study was stimulated by a prolonged scarcity of Lapua brass which I had been using for my AR-15 service rifle in XTC matches. Of greatest interest were consistency of case volume, neck wall thickness and muzzle velocty of 77grain Sierra MatchKing bullets with a standard case powder load. Data were compared for new brass cases and brass cases that had been fired once and then full-length resized and fired a second time with the standard load.

Brass Cases Tested:

Brass was obtained from various commercial dealers

|

Study Procedures

1. Brass cases were initially tested following removal from the shipping box or bag from the supplier. Unprocessed (virgin) brass without primers was used in all instances except for the Lake City brass which was once-fired military 5.56x45mm NATO brass which had been reconditioned to 223 Remington cases (deprimed, swagged, resized, trimmed and cleaned/polished) by Top Brass, LLC.

2. Cases were measured, loaded and fired

with the same standard load except where noted: 77gr Sierra MatchKing, 22.2 gr AR-Comp, CCI41 primer, 2.255" COAL. The test rifle had a White Oak Armament, 20 inch, 1:7 twist barrel with 223 Wylde chamber and Varmint profile.

3.

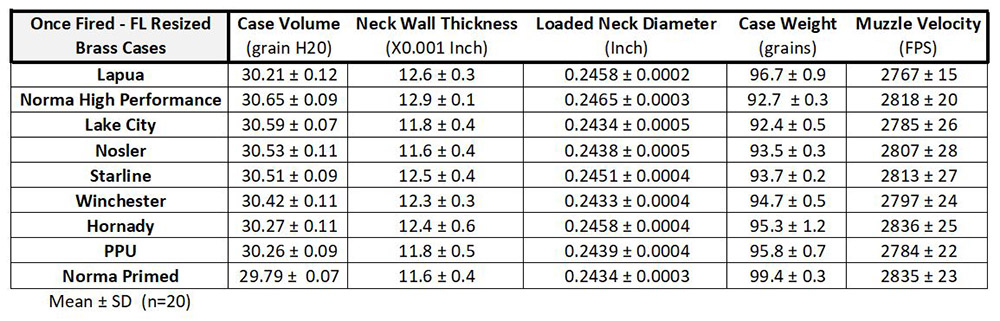

Fired cases were deprimed, cleaned, and necks were annealed. Resizing was done by full length resizing with a small base die (RCBS SB XL). Cases were gauged, remeasured, loaded with the standard load and refired.

4. Each data point is the mean and standard deviation of measurment for twenty (n=20) cases for each brand of brass.

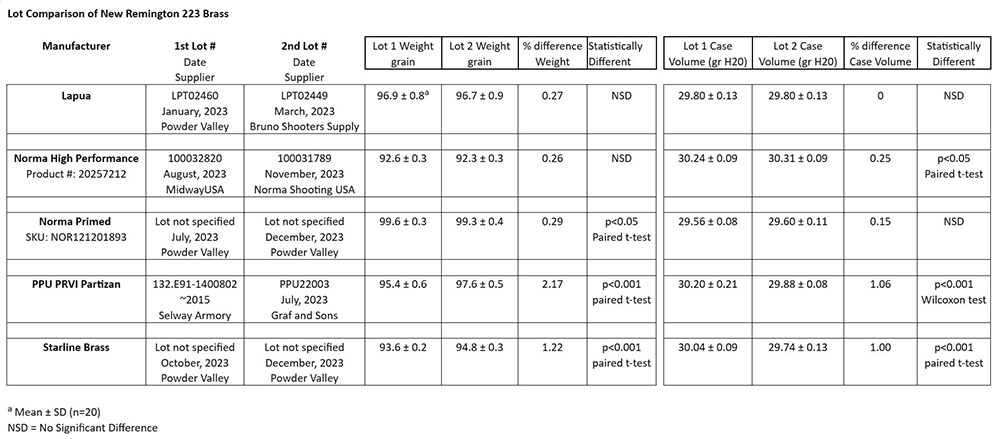

5. Characteristics of a second lot of virgin brass were compared at the end of the study to evaluate lot-to-lot variation in brass for a few brass brands.

Details of the methods are: HERE.

Results:

New (Virgin) Brass Cases

|

Failure of Primer Pocket After Full-Length Resizing with RCBS SB XL Die

Two brands of brass had loosening of their primer pockets after full-size resizing

with the small base RCBS SB XL die.

Norma High Performance brass had many loose primer pockets after resizing with the RCBS small base die and three (n=3) of 21 fired cases had primers blow out with a standard charge (See PHOTO). This was an effect of resizing with the RCBS small base die, since primer pockets remained tight after first firing and repriming without full-length resizing. Once-fired Norma HP brass had normal primer retention after resizing with another die (Redding SB FL resizing die from the National Match set). Case capacity with the Redding die is 30.47± 0.06 gr H20.

Nosler brass had similar loosening of primer pockets and two (n=2) of 21 primers blew out during the second firing (See PHOTO) after resizing with a small base die.

Lot-to-Lot Variation in New Case Properties

(Click on table for larger font table)

There were lot-to-lot variations in all of the 5 brass brands tested except Lapua which had no significant variations in case weight or capacity between lots examined. Norma brass (both primed and high performance) had small differences in either weight or volume (<0.5%) between two lots or shipments examined. PPU and Starline brass had the greatest lot-to-lot variation. For PPU, the two lots which were obtained 8 years apart had 2% differences in weight and 1% differences in case volume. Two samples of Starline brass obtained in 2023 differed by 1.2% in weight and 1% in volume.

There were lot-to-lot variations in all of the 5 brass brands tested except Lapua which had no significant variations in case weight or capacity between lots examined. Norma brass (both primed and high performance) had small differences in either weight or volume (<0.5%) between two lots or shipments examined. PPU and Starline brass had the greatest lot-to-lot variation. For PPU, the two lots which were obtained 8 years apart had 2% differences in weight and 1% differences in case volume. Two samples of Starline brass obtained in 2023 differed by 1.2% in weight and 1% in volume.

Data Summary and Conclusions

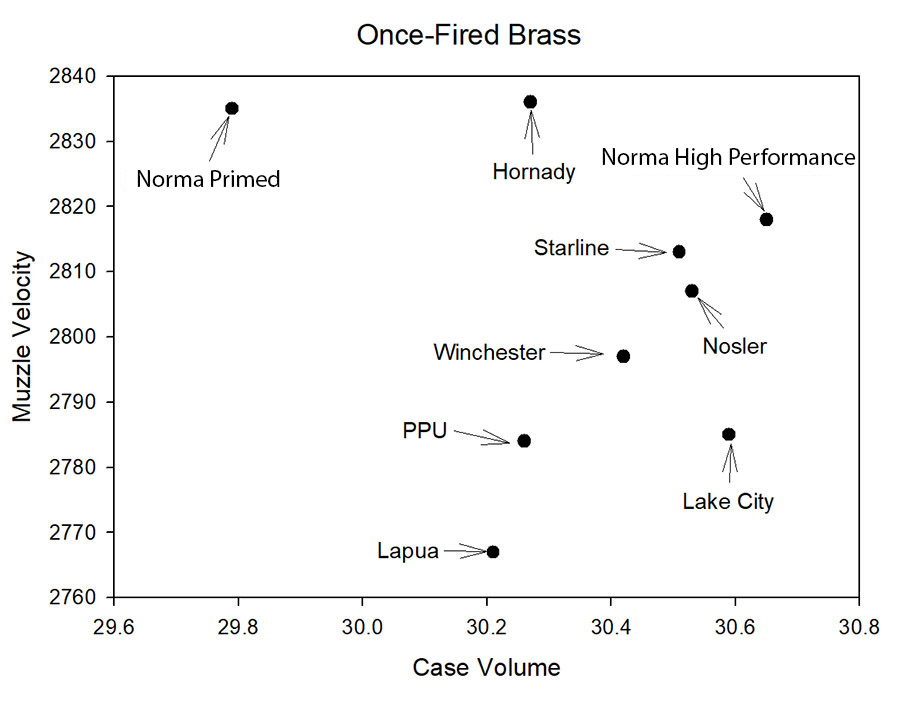

Brands of new brass out of the shipping container differed considerably in their case capacity (0.96 grains water from highest to lowest capacity). Muzzle velocity varied among brands with the standard powder charge (31 FPS from highest to lowest). Muzzle velocity standard deviations for new brass were relatively small for all brass brands studied. After firing, cleaning and full-length resizing, variations in brand case capacity remained wide (0.94 grains water), and muzzle velocity difference between brands for a standard powder charge increased to 69 FPS. During the second firing, standard deviations for muzzle velocity doubled or increased more. There was no strong correlation between case capacity and muzzle velocity with a standard charge. Standard deviations of muzzle velocity of either new brass or once-fired and full-length resized brass was lowest for Lapua brass. Lapua brass also showed the lowest variation in lot-to-lot comparison. The information is useful to consider when switching from one brass brand with a charge that has been optimized to another brand of brass.

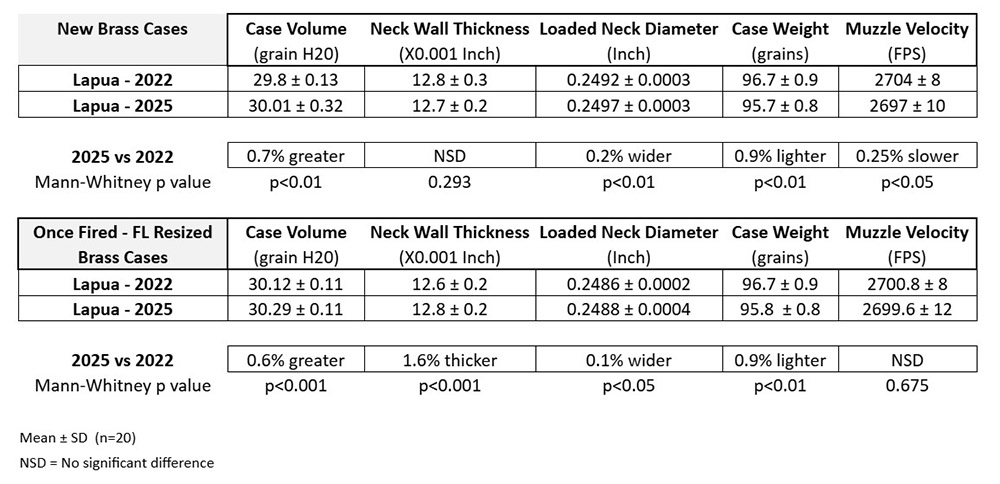

2025 Addendum on Lapua Brass

In March, 2025, I obtained shipments of newly manufactured Lapua brass from two U.S. commercial vendors (MidwayUSA and Frisco Guns). They were both from the same 2025 lot (LPT05107) and had a new style of packaging using cardboard racks and containers instead of hard plastic boxes (see photos). I compared characteristics of the 2025 manufacture brass (LPT05107) with that of brass manufactured in 2022 (LPT02449). Methods of comparison used were similar to those in the 2023 except as noted in the Methods Section. Data are posted below.

There were minimal differences in the 20 brass cases measured from lots manufactured in 2025 compared to those from 2022. Less than 1% differences were measured in case weight, case volume, neck wall thickness and muzzle velocity with standard charge. This is consistent with the previous finding of minimal lot-to-lot variation in Lapua brass as compared to that of several other manufacturers of .223 Remington brass cases.

First posted 19 November 2023; Revised 17 December 2023 and 3 April 2025

© 2023, 2025, William L. Castleman