Temperature Sensitivity of 11 Powders for .308 Winchester

The goal of these tests was to characterize temperature sensitivity of 11 powders used for loads of .308 Winchester cartridges. A highly desirable powder for a match rifle would produce only small variations in muzzle velocity across temperatures that I commonly encounter shooting in North and Central Florida (40F to 95F) and would show only small variations in shot to shot velocity at the same temperature. Because of recent powder shortages, obtaining adequate powder volumes has necessitated purchasing several different powders in order to shoot a series of matches or a season with the same powder and to use other powders for practice shooting. The temperature-muzzle velocity relationships of 11 powder samples that I have on hand were compared with .308 Winchester cartridges.

Methods:

A. Powders tested

1. IMR 8208 XBR (Lot # 1100520 7181) Manufactured by: Thales Australia Ltd (ADI), Mulwala, NSW, Australia. Brand rebadge and distributed by: IMR Powder Company, Shawnee, KS, USA.

2. IMR 4166: (Lot # 80618156415) Manufactured by: General Dynamics Ordnance and Tactical Systems, Valleyfield, Québec, Canada (Similar to XPR40C2). Brand Rebadge and distributed by: IMR Powder Company, Shawnee, KS, USA

3. IMR 4064 (Lot # 1020430 2779 ) Manufactured by: General Dynamics Ordnance and Tactical Systems, Valleyfield, Québec, Canada Brand rebadge and distributed by: IMR Powder Company, Shawnee, KS, USA.

4. Varget: (Lot # 80306207171) Manufactured by: Thales Australia Ltd (ADI), Mulwala, NSW, Australia. Brand rebadge and distributed by: Hodgdon Powder Company, Shawnee, KS, USA.

5. H4895: (Lot# 8111320 7227) Manufactured by: Thales Australia Ltd (ADI), Mulwala, NSW, Australia (Similar to AR2206H). Brand rebadge and distributed by: Hodgdon Powder Company, Shawnee, KS, USA

6. CFE 223: (Lot# 1061421 2165) Manufactured by: St. Marks Powder (General Dynamics), St. Marks, FL, USA (similar to Primex SMP-746 and SMP-842 used in Green 5.56 M855A1 ammunition). Brand rebadge and distributed by: Hodgdon Powder Company, Shawnee, KS, USA

7. Vihtavuori N140: (Lot# 02.06.2021) Manufactured by: Nammo Vihtavuori Oy, Vihtavuori, Finland. Distributed by: Capstone Precision Group, Sedalia, MO, USA .

8. Reloader 15 (RL 15): (Lot # 15051Z010622) RL 15 is made is Sweden (presumably by Eurenco Bofors AB, Karlskoga, Sweden) Brand rebadge and distributed by: Alliant Powder, Anoka, MN, USA

9. AR-Comp: (Lot # 15036 Z 051821) Manufactured by: Eurenco Bofors AB, Karlskoga, Sweden (Similar/Identical to RP-34TZ) Brand rebadge and distributed by: Alliant Powder, Anoka, MN, USA

10. Lovex S062 - Shooters World Precision Rifle Powder: (Lot# poorly legible stamp on label " ___21_ 320")

Manufactured by Expolsia, a.s., Pardubice, Czech Republic (Lovex S062). Brand rebadge as Shooters World Precision Rifle Powder and distribution by Shooters World, LLC, Tampa, FL,

11. Vihtavuori N150: (Lot# 19.01.2022) Manufactured by: Nammo Vihtavuori Oy, Vihtavuori, Finland. Distributed by: Capstone Precision Group, Sedalia, MO, USA .

B. Test Cartridge

+ Lapua .308 Winchester.: Reloaded for 7th or 8th time after annealing the neck and full-sizing the case. Necks were trimmed when needed. Case volume: 55.5 grains water.

+ CCI 200 primer

+ Hornady 168 gr BTHP loaded at 2.80" COAL.

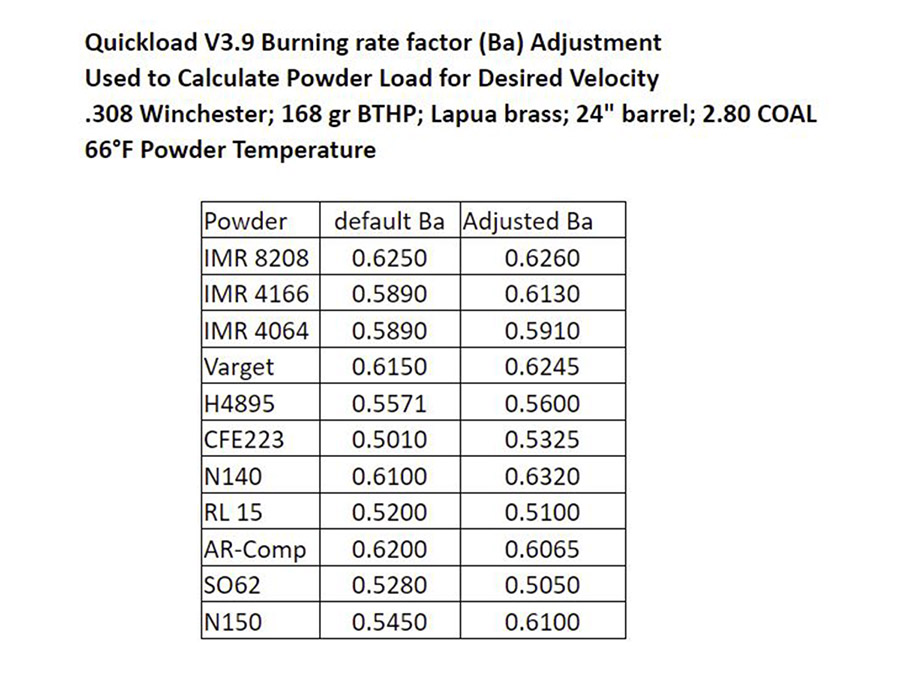

+ Powder load was estimated in an initial test using QuickLoad V3.9. Burning rate factors (Ba values) were adjusted based

on the initial test results so that each powder load would give an estimated targeted muzzle velocities between 2570 to 2600 FPS at 66F.

C. Rifle Used:

.308 Winchester bolt-action rifle, Brux M24 contour barrel, 1:11 twist, 24 inch, with bottom metal to load Accuracy International 5-round magazines. The chamber had been cut for no-trim necks. The barrel had 3540 rounds through it at the start of the test.

D. Cartridge Powder Measurement

Powders were dispensed/measured with an AutoTrickler V4 system (Adam MacDonald, New Brunswick, Canada). The system delivered powder at target weight in grains ± 0.02 grains.

E. Cartridge Powder Temperature Control

Three or two cartridges each were enclosed in water-tight 50ml centrifuge tubes and brought to target temperature by placing tubes in Yeti Rambler 36oz vacuum insulated bottles containing water at desired temperature for at least 2 to 2.5 hours.

1°C: Centrifuge tubes (2 to 3) containing cartridges at room temperature (about 21°C) were transferred to the Yeti bottles that were filled with water and ice.. They were held overnight to equilibrate, and more ice was added to containers in the morning. Water temperature was measured again with a mercury scientific thermometer (Fisher Scientific) immediately before removing the tubes to load and fire the cartridges (1°C) as a measurement of powder temperature.

19°C: Centrifuge tubes containing cartridges at room temperature (about 21°C) were transferred to Yeti bottles and filled with water at 18°C. They were held for 2 to 3 hours to equilibrate. Water temperature was measured at the time the cartridges were moved from tubes to magazines.

36°C: A similar procedure to the 3°C procedure was used except the Yeti bottles were filled with water at 38°C. They were held for 2 to 3 hours to equilibrate.

F. Firing and Chronometer Procedure

Tests were run in July, 2022 in Gainesville (elevation 176 feet above sea level).

Ambient conditions during tests ranged from 75 to 91F, 71 to 87% relative humidity, 29.90 to 29.97 mmHg barometric pressure.. At each testing period, one round was fired through the rifle to prepare the barrel and test chronograph function. One tube at a time was removed from the Yeti bottle, opened, and cartridges were dumped on a towel. Five rounds quickly were loaded by a Nitrile-gloved hand into the magazine and loaded in the rifle. Five shots immediately were fired within 12 to 20 seconds verifying each shot was measured by the MagnetoSpeed Sporter chronograph. The mean and SD of the 5 shots were recorded and each shot speed was recorded. Memory was erased after recording, and the next five cartridges were removed from tubes and loaded into the magazine and fired. The barrel was cooled with a chamber chiller between 5-shot strings.

Results/Data:

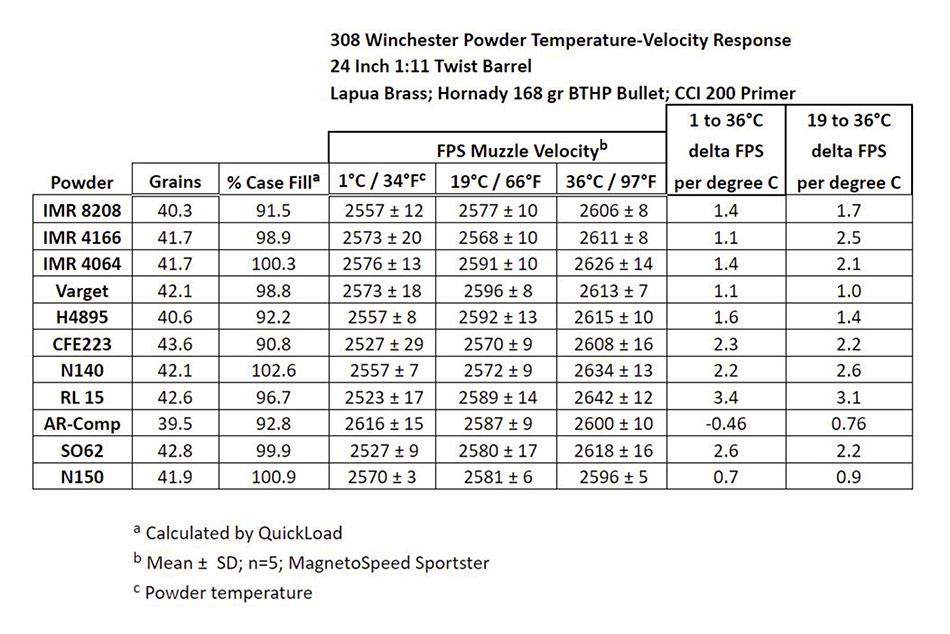

Table 1 |

|

|

|

Table 2 |

Summary:

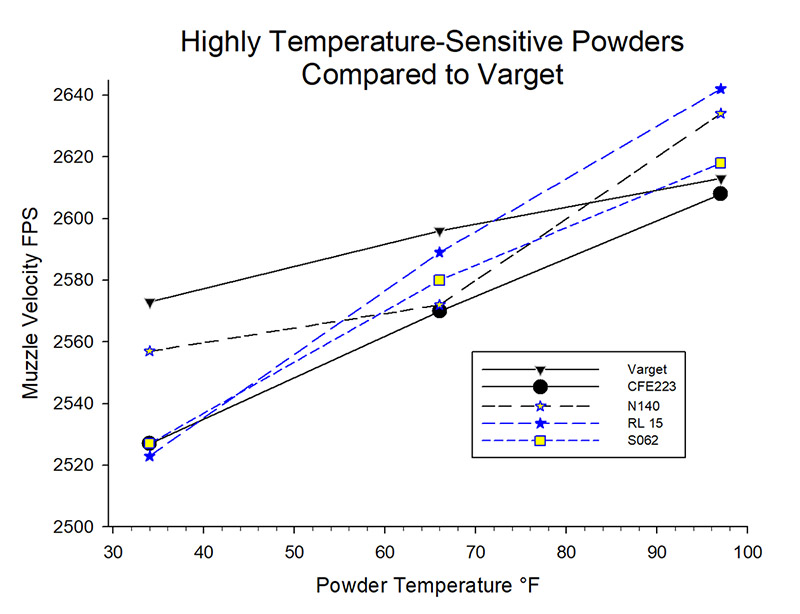

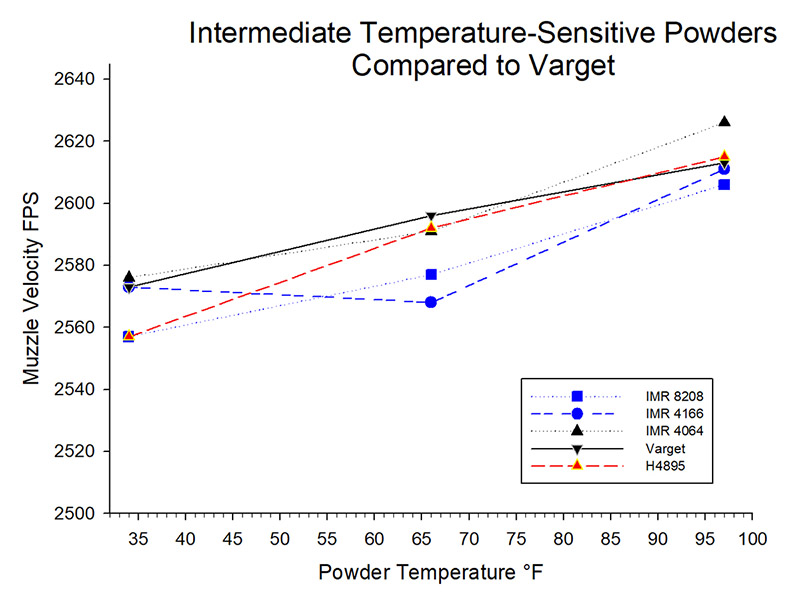

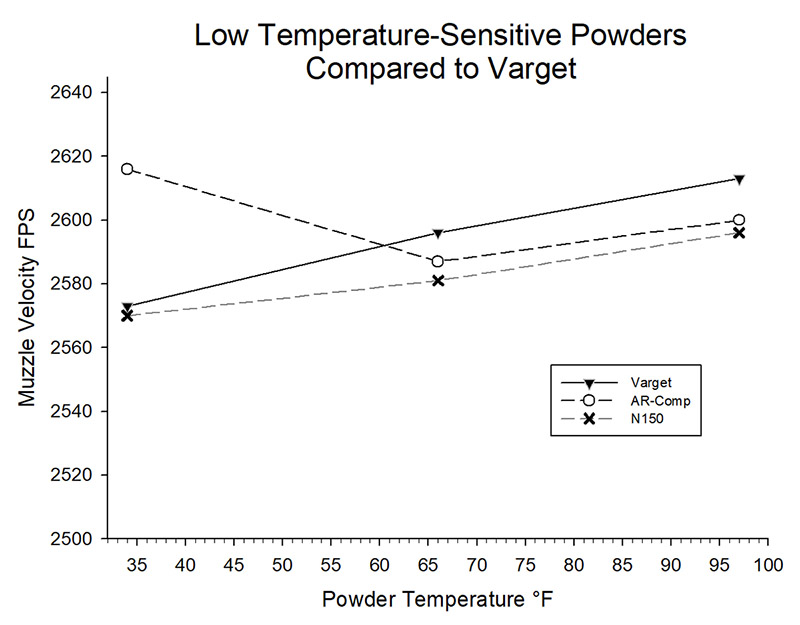

Varget is often used as a standard rifle powder for match loads of .308 Winchester and shows low-sensitivity to temperature-induced alterations in bullet velocity. Of the 11 powders studied, three broad groups of powder performance were identified that compared their performance to Varget. The criteria used focused on changes in velocity per degree increase between 1°C/34°F and 36°C/97°F and on changes in bullet velocity per degree increase between 19°C/66°F and 36°C/97°F

1. Low Temperature-Sensitive Powders: AR-Comp and N150 were less senstive to temperature-induced velocity changes than Varget.

2. Intermediate Temperature-Sensitive Powders: IMR 8208, IMR 4166, IMR 4064 and H4895 had performance results not quiet as good as those of Varget.

3. Highly Temperature-Sensitive Powders: Four powders were identified that were highly sensitive to temperature-induced velocity changes. This was especially important to me in the range between 19°C/66°F and 36°C/97°F, where Summer temperatures in Florida often occur. These powders were CFE 223, N140, Reloader 15 and SO62.